AUTOMATIC ELECTRONIC SANDERS FOR VENEERED AND VARNISHED SURFACES.

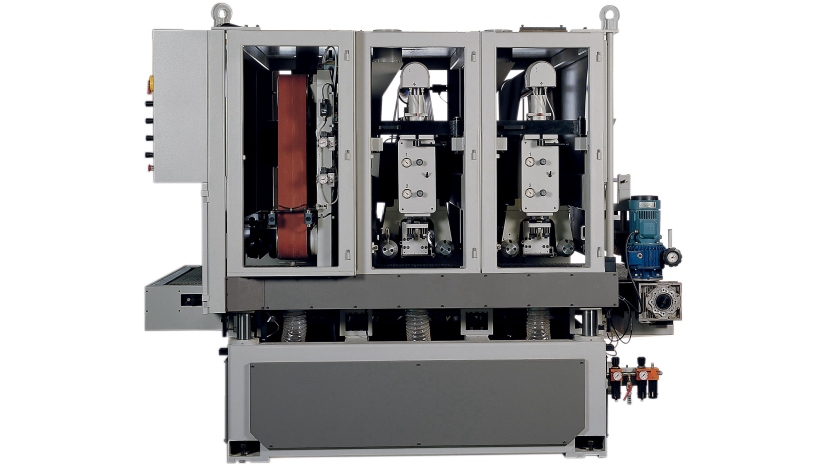

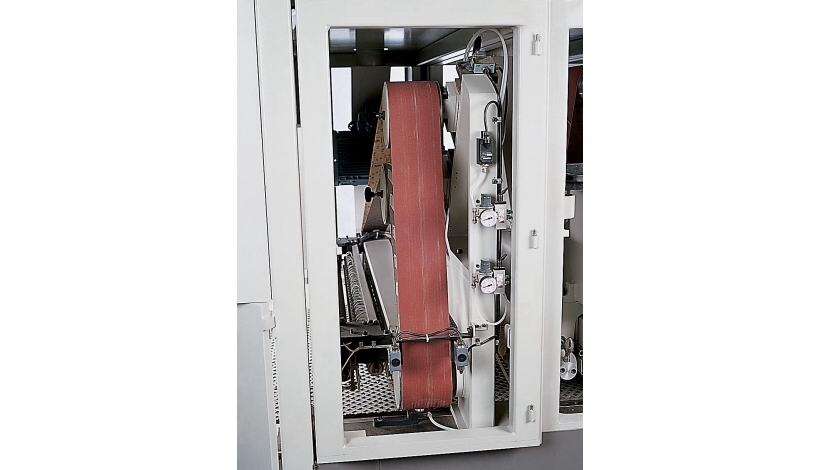

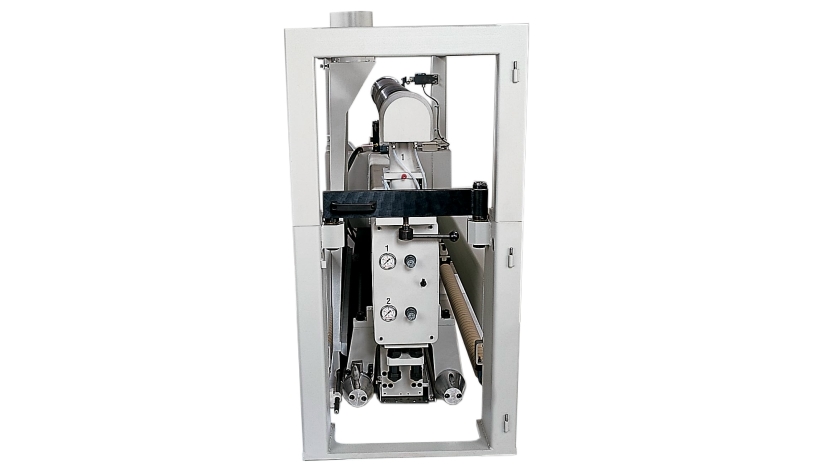

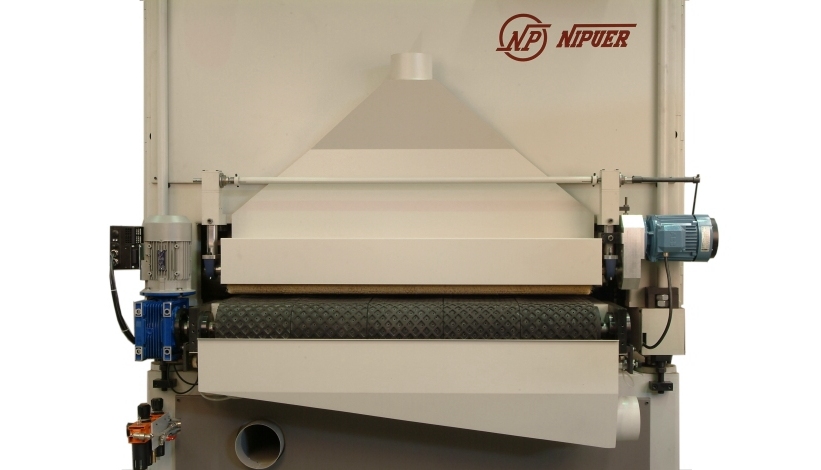

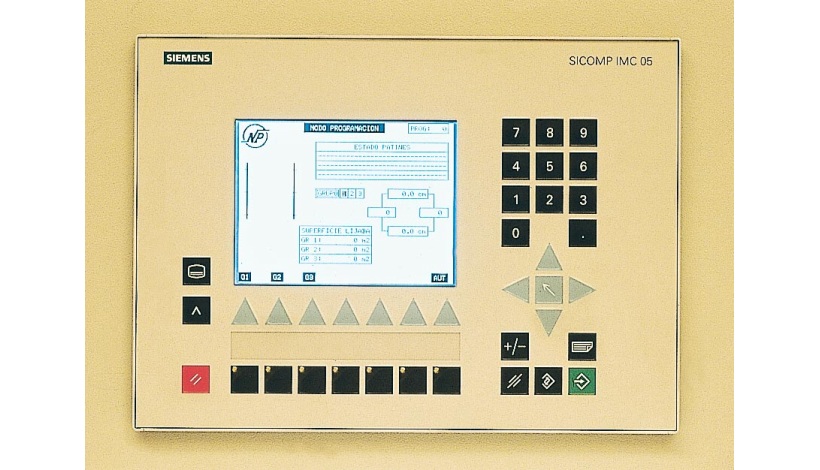

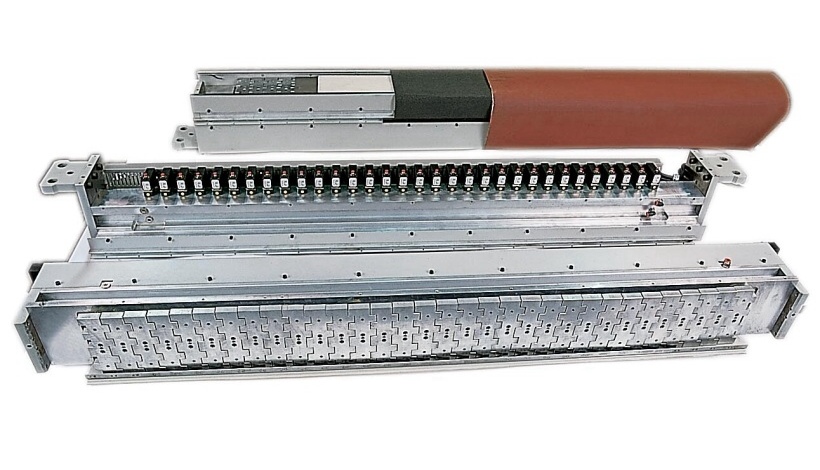

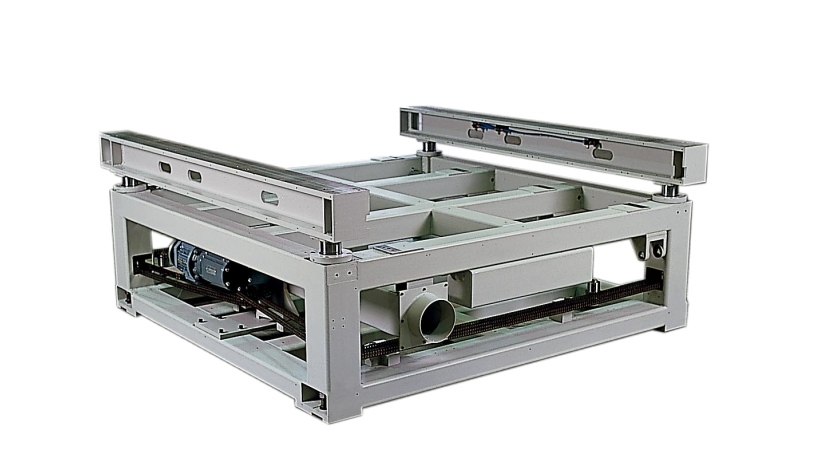

Automatic machines, prepared to work in line with fixed working table and mobile and independent groups using 4 columns each. The machine may be composed of 1,2,3 or 4 independent groups can be these: Crossed sanding groups through sectored skate. Longitudinal sanding groups through sectored skates. Gummed grooved rollers with different hardnesses and thicknesses of rubber slots. Steel grooved rollers. Scotch Britte rollers. Cleaning rollers. The machine is built in standard width of 1350 mm. and can be made for: Sanding veneered and varnished surfaces by having groups of 2 speed motors as standard and inverters under demand for continuous variation of the sandpaper cutting speed. The machine is programmable in operation being able to store programs with different working conditions, sanding speed, the offset conveyor belt input and output in each of the groups speed, lateral offsets speed, of the sandpapers cleaning groups speed and what conveyor belt enter at all times to optimize the air consumption. Feeding of the workpieces to the machine is made by a conveyor belt with adjustable feed speed and programmable from control unit, having a high flow suction system through vacuum which helps to drag the lacquer by both sides into the machine without causing unwanted movements. Scanning of the figure of the piece is produced by a series of sensors placed at the entrance of the machine and which are those that through the control unit is responsible for switching on different sectors of the skates making them down at their proper time regardless of the speed of advance of the conveyor belt leading the parts inside the machine.